Burlington-centered Thordon Bearings and Finland’s Wärtsilä have teamed up to kind the Blue Ocean Alliance to develop and market the sterntube-fewer ship notion, a structure that can save ship owners cash even though preserving the oceans from air pollution.

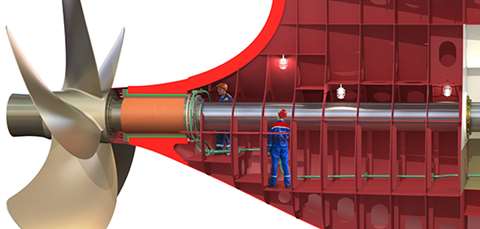

The idea of a ship style that does not need a sterntube and removes the require for oil-lubricated sterntube seals and bearings is viewed as innovative in the sector as it cuts the time of a bearing or seal substitute work from two months in dry dock to a single day when afloat.

Additional importantly, the concept demands zero environmentally harming lubricating oil.

The Blue Ocean Alliance is bringing with each other centuries of maritime industry expertise with seawater-lubricated bearings pioneer Thordon – which commenced lifetime in Hamilton additional than 100 years in the past – Helsinki-based methods integrator Wärtsilä, the University of Naval Architecture & Maritime Engineering of the Nationwide Specialized University of Athens (NTUA), naval architect Shanghai Service provider Ship Style & Exploration Institute (SDARI) and the classification society Abdominal muscles, which championed the initiative in 2019.

Stomach muscles has by now granted approval (in basic principle) to ship designer SDARI – in partnership with Thordon and NTUA -for the idea style and design of the sterntube-much less vessel with Thordon’s COMPAC Split Seawater-Lubricated Aft Bearing.

Thordon, which was honoured final thirty day period at the Global Bulk Journal Awards with the Environmental Defense Award (Maritime) for its revolutionary ThorPlas-Blue grease-free of charge bearings, is calling the sterntube-significantly less propeller shaft method structure principle T-Boss – Thordon-Blue Ocean Stern Place.

“The Blue Ocean Alliance delivers jointly a formidable partnership to acquire and further endorse the thought. The truth that various ship homeowners have presently proven curiosity in this answer is very encouraging,” claimed Thordon CEO Anna Galoni. “The T-Manager principle introduces a new solution to a service provider vessel’s aft layout – eliminating the sterntube casing, utilizing seawater for lubrication and creating a dry chamber to allow in-h2o upkeep for the to start with time.”

The T-Boss utilizes Thordon’s seawater-lubricated COMPAC propeller shaft bearing system and the Wärtsilä Enviroguard Seal, which requires no routine maintenance between planned overhauls of up to 5 decades.

The important to the design and style, defined Galoni, is in the replacement of the vessel’s sterntube cooling tank with a dry irregularly shaped chamber, enabling for inspection and servicing of a seawater-lubricated solitary bearing and seal from inside of the ship, while afloat, without having any need to have to withdraw the shaft.

“These improvements permit ship homeowners and shipyards to eliminate propeller shaft oil emissions, simplify upkeep and decreased operational fees,” Galoni reported.

inhalton’s Editorial Benchmarks and Policies

marketing